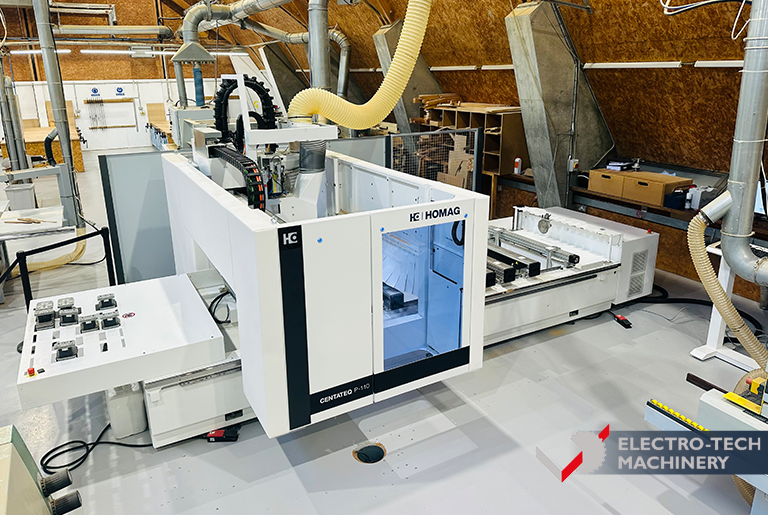

At Electro-Tech Machinery, we’re always on the lookout for equipment that helps our customers work smarter, faster, and more accurately — and the new TigerStop Pro™ does exactly that.

This fully automated positioning and push-feed system brings industrial-grade automation to virtually any workshop, transforming manual operations into efficient, high-precision workstations. Compact, robust, and remarkably intuitive, the TigerStop Pro™ is the perfect solution for businesses looking to improve throughput, reduce waste, and optimise workflow — all without taking up valuable floor space.

🚀 Powerful Performance in a Small Package

🚀 Powerful Performance in a Small Package

Despite its compact size, the TigerStop Pro™ is built to handle demanding production environments. With a pushing capacity of up to 300 lbs and precision accuracy of ±0.004″, it ensures every cut, drill, or punch is executed with consistent perfection.

The system’s brushless motor technology delivers smooth, maintenance-free operation, while the vacuum-free clamping design allows for instant setup — meaning less downtime and more productivity on the shop floor.

🧠 Smart Technology, Simple Operation

At the heart of the TigerStop Pro™ is its new 24″ touchscreen controller, offering a user-friendly interface that makes complex operations effortless. Operators can manage cut lists, adjust settings, and monitor performance with just a few taps.

The built-in Dynamic Optimisation Software calculates the most efficient cutting order, dramatically reducing material waste and increasing yield. Optional software such as Dynamic Pack Optimization™ and TigerLink 7™ allows seamless integration with existing networks, making it easy to download cut lists or sync with ERP and design systems via TigerBridge™.

🔧 Built to Last – Designed for Flexibility

🔧 Built to Last – Designed for Flexibility

Every TigerStop Pro™ system is built from cold-rolled steel and can be customised with a range of roller tables, including steel, plastic, or 10° tilted configurations. Each table features a pinch-free safety design and industrial durability to withstand continuous use.

And because the system is modular, it can easily be upgraded from existing TigerStop setups — allowing you to scale your automation investment over time.

⚙️ Key Features at a Glance

-

Accuracy: ±0.004″ for consistently precise results

-

Capacity: Pushes up to 300 lbs with roller table support

-

Control: New 24″ touchscreen interface for intuitive operation

-

Motor: Brushless design for reliability and longevity

-

Optimisation: Dynamic Optimisation Software reduces waste and overcuts

-

Connectivity: Seamless integration with network and ERP systems

-

Compact: Ideal for workshops where space efficiency matters

Ideal for Any Workshop

From small joineries to large-scale manufacturing lines, the TigerStop Pro™ is designed to improve performance at every level. Whether you’re processing timber, aluminium, or plastic, the Pro™ delivers the accuracy, consistency, and speed modern production demands — all while lowering labour costs and waste.

The result? Faster setups, better finishes, and greater profitability.

Ready to Upgrade Your Workflow?

The TigerStop Pro™ is more than just a machine — it’s an investment in precision, productivity, and smarter manufacturing.

To learn more, contact Electro-Tech Machinery today and see how the TigerStop Pro™ can transform your production.