Product Description

We can supply you with the vast range of options and accessories Homag has to offer. All Homag Edge Bander Machines come configured to suit your specifications.

Contact us to enquire about this product

If you are interested in this product and wish for a customised quote, contact us at the number +44 (0) 28 8674 8863 or fill in the enquiry form below and we will be happy to provide you with more info!

We can supply you with the vast range of options and accessories Homag has to offer. All Homag Edge Bander Machines come configured to suit your specifications.

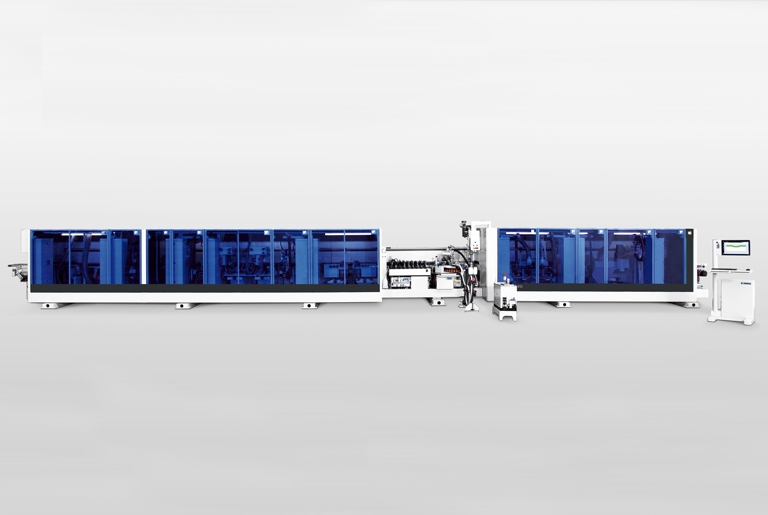

Edge bander machines EDGETEQ D-600 | D-610 profiLine – High-performance edge banders offering compact to tailored solutions

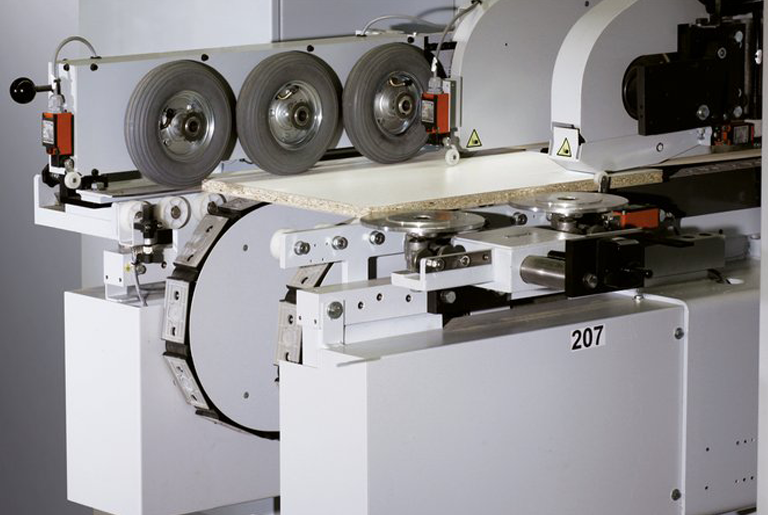

With the highly efficient Edgeteq D-600 | Edgeteq D-610 profiLine series, you can format, profile, and edge your furniture workpieces on two sides in a single run.

Double-sided machines and machine lines are used to produce medium to large outputs at a high-performance level with minimum changeovers.

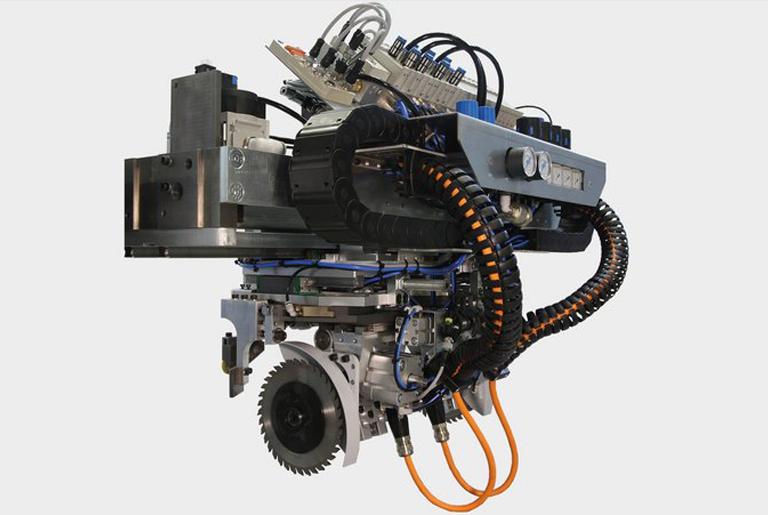

This edge bander series has an optimised chip and offcut disposal system direct waste away from the tool blades at a low suction speed, service life is considerably extended with a waste disposal detection rate of over 97%.

Additional information

| Machine Category | New Machines |

|---|---|

| Machine Function | Woodworking |

| Machine Type | Edgebanders |

| Workpiece thickness [mm] | min. 12 [mm] (optional 8 [mm]) |

| Edge thickness coils | min. 0.3 [mm]–max. 3 [mm] |

| Brand | Homag |

Technical Data

| EDGETEQ D-610 profiLine | |

|---|---|

| Machine length | 6,650–12,880 [mm] |

| Workpiece width | |

| Machines 1 | min. 195 [mm] |

| Machines 2 | min. 250 [mm] |

| Workpiece thickness | min. 12 [mm] (optional 8 [mm]) |

| max. on request | |

| Edge thickness coils | min. 0.3 [mm]–max. 3 [mm] |

| Feed speed | up to 50 [m/min] lengthwise |