Product Description

We can supply you with the vast range of options and accessories Kuper has to offer. The Kuper EFS Single-Knife Veneer Guillotine comes configured to suit your specifications.

Contact us to enquire about this product

If you are interested in this product and wish for a customised quote, contact us at the number +44 (0) 28 8674 8863 or fill in the enquiry form below and we will be happy to provide you with more info!

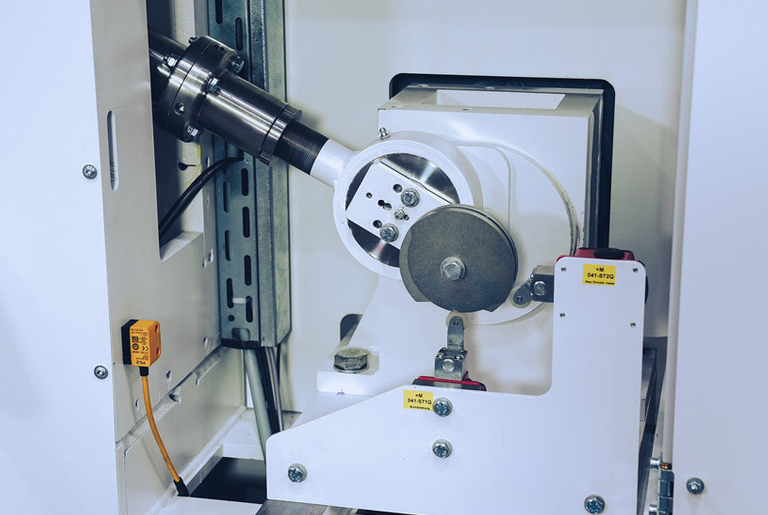

When it comes to the art of veneer cutting, precision is paramount. The KUPER EFS Single-Knife Veneer Guillotine is engineered to deliver rapid, precise cuts for your material stacks, ensuring clean, tear-free, and parallel cutting edges—a fundamental requirement for impeccable joints.

Key Features:

- Swinging Knife Motion: The KUPER EFS employs a unique swinging knife motion, cutting at an angle of 20 degrees. This motion guarantees the highest cutting quality, even when cutting across the fibre direction of the veneer.

- Narrow Design, Clear View: The machine’s narrow design provides an unobstructed view of your material and cutting surface, ensuring every cut is flawless. A guide light marks the cutting line, guaranteeing ultra-precise cuts.

- Precision Positioning: Width dimensions are automatically adjusted through integrated positioning control. The pressure bar is lowered, and the cut is initiated as soon as the target pressure is reached.

- Versatile Setup: For optimal results, we recommend combining the KUPER EFS with the KUPER QFS cross-cutting clipper. The support table, complete with a rip fence, offers ample space for handling even wide materials comfortably.

Advantages at a Glance:

- High-Quality Cuts: The swinging knife motion at a 20° angle ensures impeccable cut quality.

- Parallel Fence: Equipped with high-speed motor-driven positioning, fine adjustment, and a digital gauge for cutting parallel face veneers and edge lippings.

- Visible Cutting Line: A green guide light clearly marks the cutting line.

- Alignment Assistance: Guide markings and an angular fence on the machine table facilitate material alignment.

- Broad Pressure Bar: Suitable for pressing even wavy veneer materials level prior to cutting.

- Precut Facility: Offers hydraulic adjustment of the cutter bar by 0.9 mm for right-angled cut faces.

- Crank Drive: Enables cutting veneer across the grain with ease.

- Sturdy Construction: Absorbs high pressing and cutting forces reliably.

- Parallel Guidance: Ensures precise and permanent alignment of machine components.

- Long-lasting Knife: Features a 30 mm grinding allowance for extended use.

- Efficient Operation: Intermittent drive operation results in lower energy consumption and reduced noise levels.

- Safety Assured: Complies with occupational safety regulations, including light barrier safety devices, two-hand operation, electric safety control systems, and protective gratings at the rear.

Deep Support Table:

The support table accommodates cutting dimensions from 20 to 720 mm in width, with a stable rip fence managed by the machine control. Experience precision, speed, and efficiency, resulting in dimensionally accurate, parallel cutting edges.

Optional Precision Cut:

For thicker and more challenging veneers, the precision cutting device ensures even more precise cuts, eliminating chipping on the undersides of the veneers.

Materials Cut by the KUPER EFS:

- Veneer

- PVC

- All-plastic

- Polystyrene

- Acrylic

- Honeycomb boards

- Papers

- Plastic films

- Cardboard

- And much more

Technical Data:

Kuper EFS 2800

- Cutting length 2,800 mm

- Insertion height 80 mm

- Parallel fence range 20-720 mm *

- Pressure-bar hydraulic cylinder, 2 pressure stages

- Cutter bar brake motor, gearing, crank drive

- Parallel fence three-phase a.c. motor, positioning drive

- Connected load 7 kW **

- Floor space (with parallel fence) 496 x 182 cm

- Height 170 cm

- Net weight 3,900 kg

Kuper EFS 3200

- Cutting length 3,200 mm

- Insertion height 80 mm

- Parallel fence range 20-720 mm *

- Pressure bar hydraulic cylinder, 2 pressure stages

- Cutter bar brake motor, gearing, crank drive

- Parallel fence three-phase a.c. motor, positioning drive

- Connected load 7 kW **

- Floor space (with parallel fence) 537 x 182 cm

- Height 170 cm

- Net weight 4,300 kg

Kuper EFS 4200

- Cutting Length: 4,200 mm

- Insertion Height: 80 mm

- Parallel Fence Range: 20-720 mm (*Different ranges available upon request)

- Pressure Bar: Hydraulic Cylinder, 2 Pressure Stages

- Cutter Bar: Brake Motor, Gearing, Crank Drive

- Parallel Fence: Three-Phase A.C. Motor, Positioning Drive

- Connected Load: 7.7 kW (**Electric controls on the left if requested)

- Floor Space (with Parallel Fence): 636 x 182 cm

- Height: 170 cm

- Net Weight: 5,400 kg

Additional information

| Machine Category | New Machines |

|---|---|

| Machine Function | Woodworking |

| Brand | Kuper |

| Machine Type | Veneering |

Make an Enquiry

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.