Product Description

We can supply you with the vast range of options and accessories Kuper has to offer. The Kuper FLI 1000 Veneer Splicing Machine comes configured to suit your specifications.

Contact us to enquire about this product

If you are interested in this product and wish for a customised quote, contact us at the number +44 (0) 28 8674 8863 or fill in the enquiry form below and we will be happy to provide you with more info!

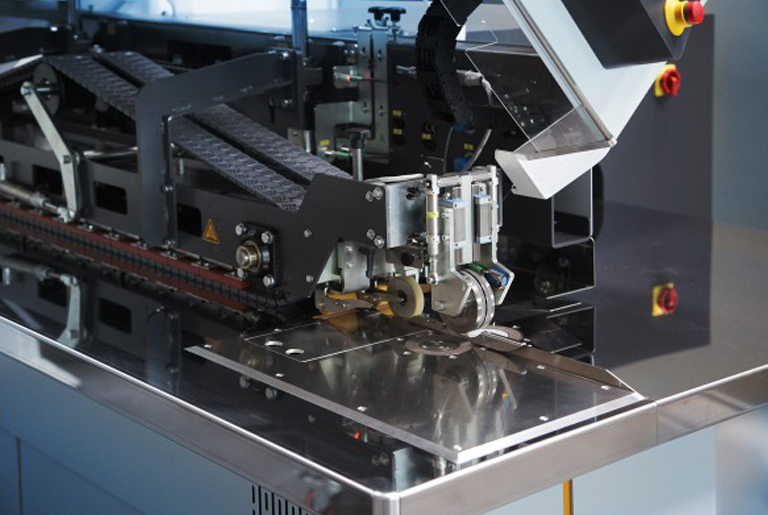

When it comes to joining precious veneers with utmost precision and efficiency, the Kuper FLI 1000 Veneer Splicing Machine takes centre stage. The FLI seamlessly blends innovation with time-tested technology to deliver unparalleled results.

Precision Veneer Splicing: The Kuper FLI is the culmination of innovative technology and the highest manufacturing standards, guaranteeing precise veneer splicing. It incorporates a proven heat supply method, simultaneous contact pressure application, and precise material guidance, all complemented by intelligent energy management.

User-Friendly Control: The machine features an intuitive, robust control panel that remains responsive even when operated with gloves. It displays all essential parameters, significantly reducing machine start-up time.

Precision Glue Application: Our innovative glue application system ensures precise adhesive application for veneers of varying thicknesses.

Expanded Performance: The machine’s performance range is further extended by an integrated compact cooling unit, significantly prolonging the life of the glue pot. Additionally, optional packets are available for processing micro and thick veneers, ensuring versatility in your operations.

Key Advantages at a Glance:

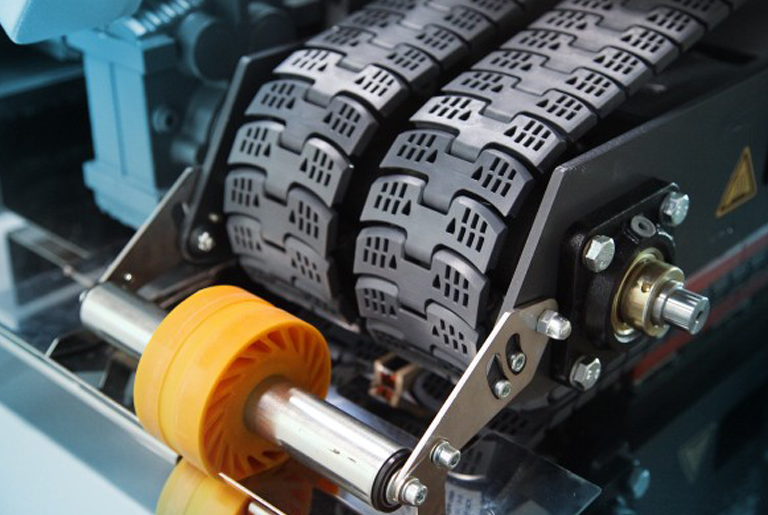

- Maintenance-Free Efficiency: High-efficiency plastic chains not only guarantee maintenance-free operation but also prevent heat conduction and unsightly stains.

- Efficient Heating: The heating system boasts high efficiency, with an effective heating width of only 12 mm, ensuring energy is used optimally.

- Intelligent Energy Management: Our advanced energy management system enhances capacity and improves standby mode, promoting sustainability and cost-efficiency.

- Innovative Veneer Infeed: The FLI features an innovative veneer infeed device equipped with a disc gear and tolerance compensation mechanism, ensuring an offset-free material feed.

- Integrated Glue Application: A cutting-edge integrated glue application system enables precise adhesive application on a single side, minimizing waste and ensuring a strong bond.

- Robust Control Panel: The control panel is designed to withstand various conditions, and its storage function enhances ease of use.

- Compact Cooling Unit: An integrated cooling unit not only prolongs the life of the glue pot but also enhances overall machine performance.

Technical Specifications:

- Veneer thickness: 0,4 – 2,5 (optional from 0,25 and up to 5,0) mm

- Veneer width: from approx. 35 mm

- Veneer length: from approx. 300 mm

- Space required (L x B x H): 2.300 x 1.820 x 1.500 mm

- Throat depth: 000 mm

- Feed speed: 12 – 55 m/min.

- part Id-no.: 1000

- type: FLI 1000

- comment: Additional technical data upon request.

- Illustrations may contain options.

Choose the Kuper FLI 1000 Veneer Splicing Machine for a perfect blend of efficiency, precision, and innovation in your veneer glueing operations.

Additional information

| Machine Category | New Machines |

|---|---|

| Machine Function | Woodworking |

| Machine Type | Veneering |

| Brand | Kuper |

Make an Enquiry

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.