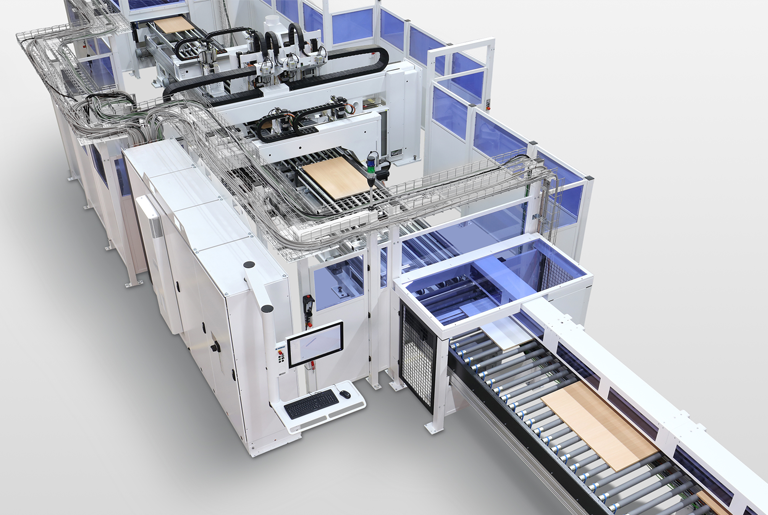

Product Description

We can supply you with the vast range of options and accessories Kuper has to offer. The KUPER QFS Cross-Cutting Clipper comes configured to suit your specifications.

Contact us to enquire about this product

If you are interested in this product and wish for a customised quote, contact us at the number +44 (0) 28 8674 8863 or fill in the enquiry form below and we will be happy to provide you with more info!

When precision is your priority for cross-cutting material stacks, look no further than the KUPER QFS Cross-Cutting Clipper. Whether you’re dealing with paper, plastic sheets, or veneer packages, the KUPER QFS ensures rapid, tear-free cuts with vertical knife movement. Say goodbye to rough cutting edges and hello to perfection.

Key Features:

- Vertical Knife Movement: The KUPER QFS’s vertical knife operation guarantees tear-free cutting, ensuring clean edges and impeccable results. This versatility allows you to cut various materials with ease.

- Rapid and Precise: This machine doesn’t compromise on speed or precision. It swiftly and accurately cuts through materials, providing high-quality results every time.

- Guide Light: A guide light marks the cutting line, guaranteeing precision and accuracy in every cut.

- Powerful Knife Motion: The KUPER QFS is equipped with a brake motor, gear drive, and crank drive that ensure a rapid and powerful knife motion, maintaining Kuper’s commitment to exactness.

Operational Ease:

- Measuring Tapes: Length dimensions can be conveniently read from two measuring tapes.

- Two-Hand Control: The pressure bar is lowered synchronously with the knife, and the cut is triggered by a two-hand control device.

- Excellent Visibility: The machine’s narrow design provides an excellent view from all sides of the material and cutting area. It can be operated on either the right or left side of the cutting surface.

- Angular Arrangement: The KUPER QFS allows for angular arrangement both to the left and right, or on both sides at a longitudinal veneer guillotine. Supporting tables are dimensioned accordingly.

Flexible Configuration:

- Knife Bezel Placement: For the finishing cycle from left to right, the knife bezel of the KUPER QFS is on the right. If desired, the guillotine can be delivered rotated by 180° – with the knife bezel on the left.

- Extended Supporting Tables: Longer supporting tables with pedestals and longitudinal stops are optionally available, providing flexibility to meet your specific needs.

Safety First:

- Plexiglass Guard: A plexiglass guard enhances safety during operation.

- Plug-In Angular Stops: These stops enhance precision and safety.

- Electric Control System: A safety-oriented electric control system ensures secure operation.

Materials Cut by the KUPER QFS:

- Veneer

- PVC

- All-plastic

- Polystyrene

- Acrylic

- Honeycomb boards

- Papers

- Plastic films

- Cardboard

- And much more

Technical Data:

- Cutting Width: 850 mm

- Insertion Height: 60 mm

- Max. Thickness of Single Sheet (for sliced and peeled veneers): Approx. 3 mm

- Running Time of Knife per Cut: 1.5 seconds

- Motor Output: 3.5 KW

- Floor Space x Height (without supporting tables): 112 x 60 x 140 cm

- Dimensions of Seacase: 121 x 75 x 150 cm

- Net Weight: 480 kg

Note: Additional technical data and customization options are available upon request. Illustrations may include optional features. Additional components, such as control cabinets and safety facilities, may not be shown in illustrations. The design is subject to modification to meet your specific requirements.

Additional information

| Machine Category | New Machines |

|---|---|

| Machine Function | Woodworking |

| Brand | Kuper |

| Machine Type | Veneering |

Make an Enquiry

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.