Product Description

Contact us to enquire about this product

If you are interested in this product and wish for a customised quote, contact us at the number +44 (0) 28 8674 8863 or fill in the enquiry form below and we will be happy to provide you with more info!

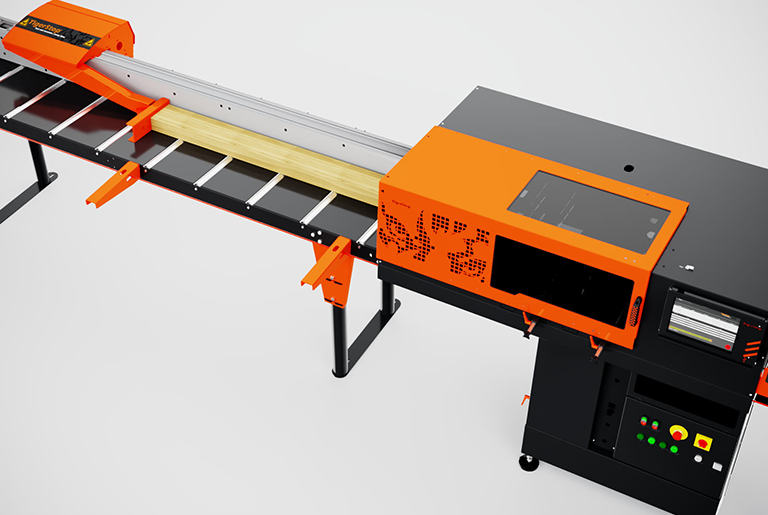

Fast. Precise. Built for High-Volume Production.

The TigerSaw 1000™ is a fully automatic, push-feeding, optimising saw system for high-speed cutting of wood and plastic materials. Designed for manufacturers who demand accuracy, throughput, and value, TigerSaw 1000™ comes equipped with advanced defect marking, material optimisation, and bundle cutting capabilities—all backed by powerful TigerTouch™ software.

From crayon defecting to dynamic cut list optimisation and grading, TigerSaw 1000™ is built to deliver precision parts at scale while reducing scrap, labour, and material costs.

Highlights

-

Accuracy: ± 0.012”

-

Material: Wood & Plastics

-

Push Capacity: Up to 2,100 lbs (with HeavyDuty 2)

-

Max Length: 108 ft

-

Fully Automated with Dynamic Optimization™

-

Crayon Defect Marking + Grade Sorting

-

Cut List Downloading + Simulation Tools

-

Optimised for Pack & Bundle Cutting

-

Adjustable Cutting Envelope: 6.25″ x 6.25″ to 1.25″ x 16″

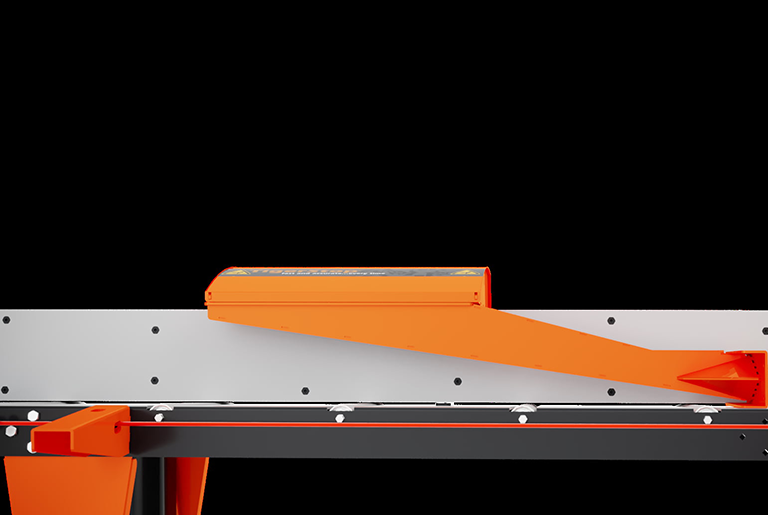

Push Feeding Options

-

TigerStop Pro – Up to 300 lbs

-

TigerTurbo – Up to 840 lbs

-

HeavyDuty 2 – Up to 2,100 lbs

Software Features

-

Dynamic Optimization™ – Maximise material yield from every cut

-

TigerBridge™ – NEW software for seamless workflow connectivity

-

TigerLink 6 & 7 – Cut list downloading from TigerTouch® and networked PCs

-

Crown+Miter Pro & Flooring Optimisation – Specialised cutting routines

-

Framing & Panel Optimisation – Ideal for glue-up, windows, and doors

-

Value-Based Optimisation – Prioritise cut list by part value

-

Crayon Defecting – Easily mark and skip defects in real-time

-

Grade Marking – Sort by up to 3 material grades using UV crayon

-

Simulation & Reporting – Estimate job yields, generate PDF reports

-

Dynamic Pack Optimisation – Optimise bundle cuts with precision

-

Cascading Cut Lists – Process jobs in sequence for nonstop production

Technical Specifications

- Accuracy – ± 0.012 inch

- Max Pushing Capacity – Up to 2,100 lbs

- Max Material Length – Up to 108 ft

- Cutting Envelope – 6.25″ x 6.25″ to 1.25″ x 16″ or 6.625″ OD

- Material Types – Wood & Plastics

- Motor Power – 10 HP (7.5 kWh)

- Power Supply – 3-Phase (208V, 230V, 480V)

Tables & Integration

-

Cold-rolled Steel Tables – Pinch-free design

-

Roller & Tilt Options – Steel, plastic, or 10° angled tables

-

Mounting Flexibility – Works with AutoLoader and existing workflows

Accessories Available

-

Saw blades for various materials

-

UV crayon defecting system

-

Label printers and scanners

-

AutoLoader™ Automatic Infeed Station

-

Clamping systems and light curtains

Your Competitive Edge

Whether you’re cutting door panels, flooring packs, bundled trim, or random-width lumber, the TigerSaw 1000™ is the tool to:

-

Reduce scrap and labour

-

Maximise material yield

-

Increase throughput

-

Minimize rework

-

Automate grading, defecting, and job tracking

Additional information

| Brand | TigerStop |

|---|---|

| Machine Category | New Machines |

| Machine Function | Woodworking |

| Machine Type | Automatic Saw |

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.