Product Description

Contact us to enquire about this product

If you are interested in this product and wish for a customised quote, contact us at the number +44 (0) 28 8674 8863 or fill in the enquiry form below and we will be happy to provide you with more info!

Powerful, Precise, and Space-Efficient Material Handling

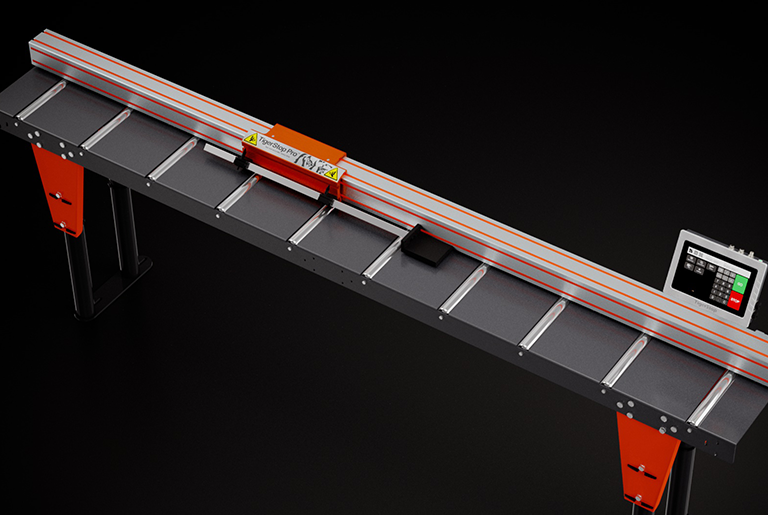

The all-new TigerStop Pro™ delivers fast, accurate positioning and push-feeding in a compact system that transforms manual machinery into fully automated, high-efficiency workstations. Designed for demanding manufacturing environments, TigerStop Pro™ handles heavy materials with ease—offering unmatched precision and productivity in just a small footprint.

Whether you’re cutting, drilling, or punching, the TigerStop Pro™ brings automation and accuracy to any process, making it an essential upgrade for workshops of all sizes.

Highlights

-

Accuracy of ±0.004″ ensures consistently precise results

-

Push-feeds material up to 300 lbs with roller table support

-

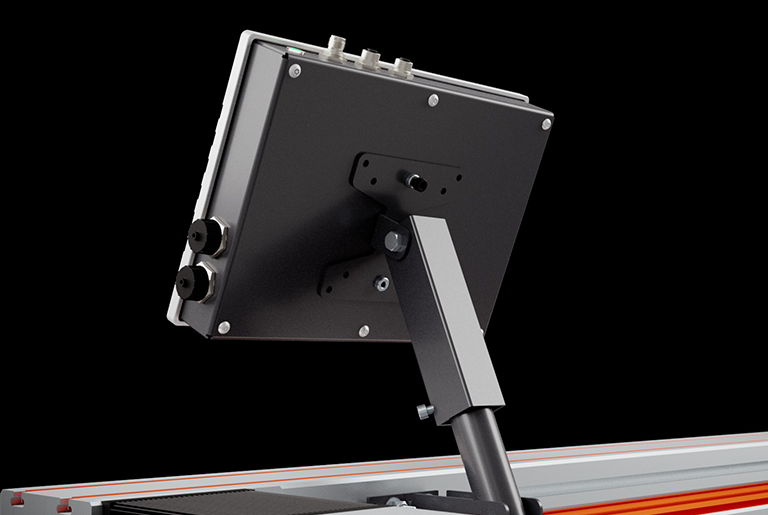

New Touchscreen Controller for simple, intuitive operation

-

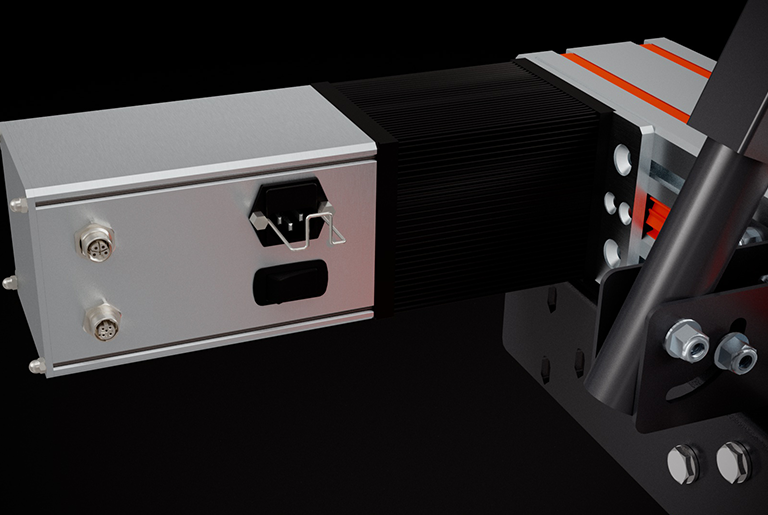

Brushless motor technology for increased reliability and lower maintenance

-

Dynamic Optimization Software maximizes material yield

-

Cut list downloading and label printing streamline workflow

-

TigerBridge connects seamlessly to third-party software systems

Features

-

Fully automated material positioning and push-feeding

-

Vacuum-free clamping design – zero setup time

-

New TigerBridge software for seamless integration

-

Optional Dynamic Pack Optimization for efficient bundle processing

-

Compact footprint ideal for space-conscious workshops

-

Touchscreen user interface for quick training and operation

-

Customisable with a range of accessories and roller tables

-

Easily upgrade from existing TigerStop systems using an upgrade kit

-

Reduces waste and eliminates overcuts with smart software controls

Technical Data

- Accuracy – ± 0.004 inch

- Max Pushing Capacity – 300 lbs (with roller tables)

- Max Material Length – Up to 30 ft

- Belt Type – 32 mm

- Motor – Brushless

- Controller – 24″ Touchscreen Interface

- Installation Footprint – Varies based on table options

Optional Software Upgrades

-

Dynamic Optimization™ – Calculates the most efficient cutting order to reduce waste

-

Dynamic Pack Optimization™ – Optimises cutting of bundled materials

-

TigerLink 7™ – Download cut lists from your network directly to your machine

-

Label Printing – For clear part identification and workflow efficiency

-

TigerBridge – Integration with third-party design and ERP software

Table Options

Strong, Safe, and Built to Last

Choose from steel roller tables, plastic roller tables, or 10° tilted tables. All table systems are built from cold-rolled steel and feature pinch-free safety design for optimal operator comfort and durability.

Ideal for Any Workshop

From small joineries to large-scale production lines, TigerStop Pro™ is built to boost efficiency, improve accuracy, and maximise your material yield—no matter the size of your operation.

Additional information

| Brand | TigerStop |

|---|---|

| Machine Category | New Machines |

| Machine Function | Woodworking |

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.