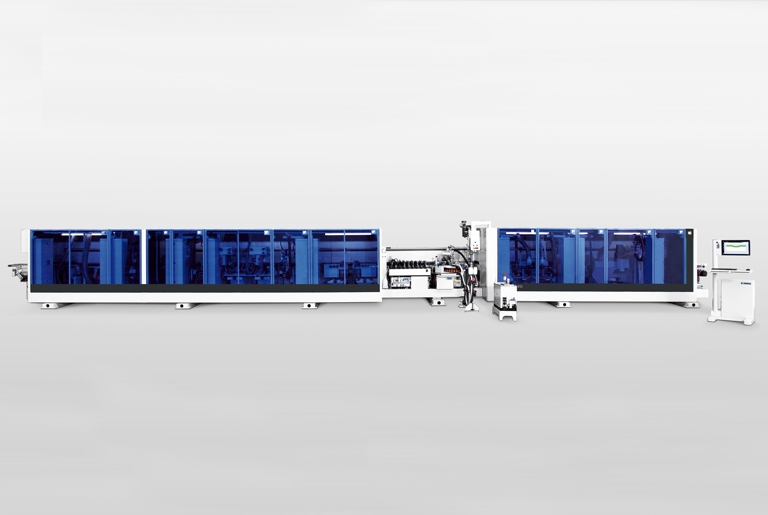

Untha LR1000/1400 wood shredder

LR1000

- 22 / 30 / 2 x 18,5 kW Rated capacity:

- 1.000 x 1.050 / 1.600 mm Feed opening:

- 15 – 40 mm Fraction sizes (based on the screen):

- 8 srm/h Maximum throughput capacity:

LR1400

- 30 / 2 x 22 / 2 x 30 kW Rated capacity:

- 1.400 x 1.050 / 1.600* mm Feed opening:

- 15 – 40 mm Fraction sizes (based on the screen):

- 10 srm/h Maximum throughput capacity:

LR1000 and LR1400 are the largest of the LR shredder range, and therefore particularly suitable for joinery and sawmill plants and for the woodworking industry, where large quantities of waste wood are accumulated. These two powerful LR-class machines are used for demanding shredding work, for which high throughputs are required. The wood shredders are able to develop their full performance capacity from waste wood quantities of 12 m³ per week. The configuration comprising a long rotor, a large, perforated screen surface and optimised cutter geometry provides superior performance. For high efficiency, the LR1000/1400 shredders feature cutting tools with a specific blade design which can shred whilst consuming very little energy. In addition, the motor shuts down automatically if no material is fed into the machine for more than 3 minutes. This saves energy whilst simultaneously reducing operating costs. The intelligent drive control shuts the shredder motor down automatically in the case of foreign objects. In addition, the shredders have been equipped with an automatic reverse function to prevent motor overload. The LR1000/LR1400 shredders are ideal for shredding hardwood, softwood, OSB board, chipboard, MDF sheets, veneers, off-cuts, construction timber and pallets. The large end product quality produced by the shredder is ideal as high-quality wood chips for incineration in a wood chip heating system, or for the manufacture of wood briquettes.

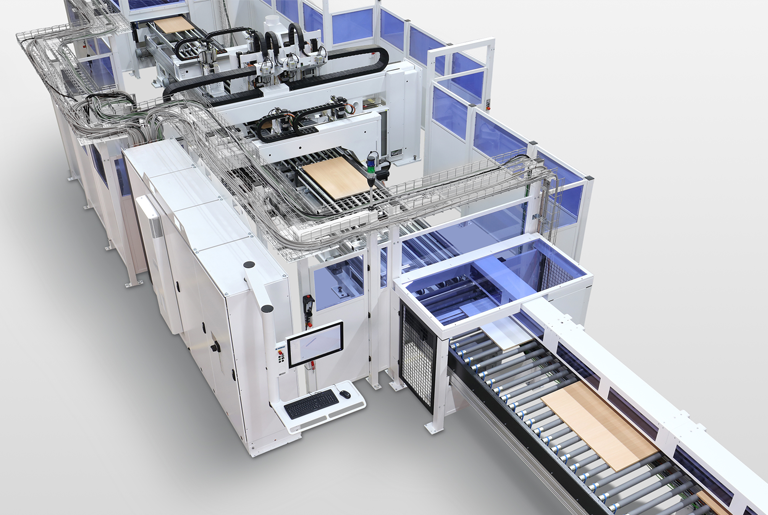

Accessories

3-year care-free warranty on purchasing an UNTHA wood shredder ( or 2,000 hours, depending on which is reached first.)

Pipe magnets

Each shredder is equipped with pipe magnets to separate metal pieces from the wood. We can offer you different pipe magnets depending on your application.

Extraction

Extraction hood – easily connect your existing extraction system to the wood shredder and transport the granulate to the chippings and shavings silo.

Flexible conveyor screw

Shaftless conveyor spirals are a cost-effective alternative to traditional conveyor screws. The flexible conveyor spirals come in various lengths and diameters. Untha offers a customised solution for your application.

Conveyor screw

Wood shredders can be equipped with a discharge screw as well as a conveyor screw. Depending on your application, Untha offers you customised solutions in various lengths and inclines.

Conveyor belt with magnet separator

Infeed and discharge conveyor belts – will be optimally adapted to the on-site conditions and the desired throughput performance of the shredder. Ensure efficient metal separation with conveyor belts equipped with a magnet separator at the pulley.

Hopper

Hopper can be adapted to your needs depending on the infeed.

Hydraulic tilt table

The tilt table enables you to reliably shred particularly long residual timber. The tilt table is directly connected to the shredder and automatically tilts the material into the hopper.

Supporting frame

Customized substructures offer you maximum flexibility. The wood shredder is thus easily adapted to the on-site conditions and to your existing conveyor technology.

Additional information

| Brand | Untha |

|---|

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.