Product Description

Contact us to enquire about this product

If you are interested in this product and wish for a customised quote, contact us at the number +44 (0) 28 8674 8863 or fill in the enquiry form below and we will be happy to provide you with more info!

We can supply you with the vast range of options and accessories Homag has to offer. All Homag Edge Bander Machines come configured to suit your specifications.

Edge bander EDGETEQ S-500 Optimat and profiLine – Comprehensive equipment standard

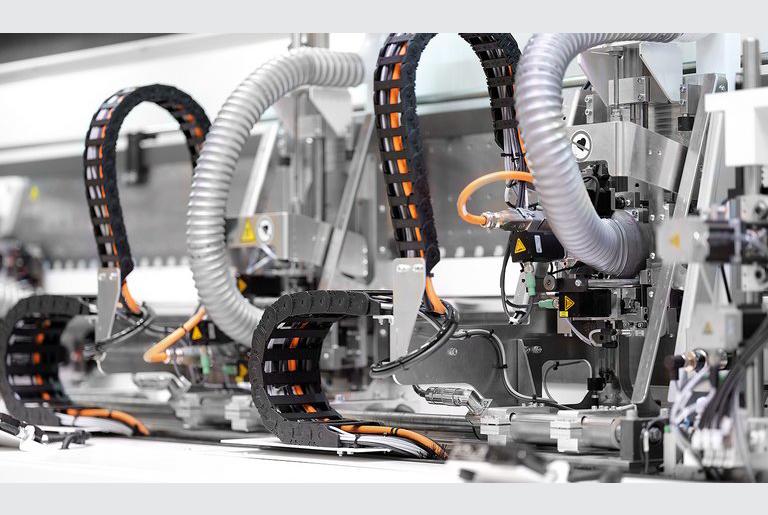

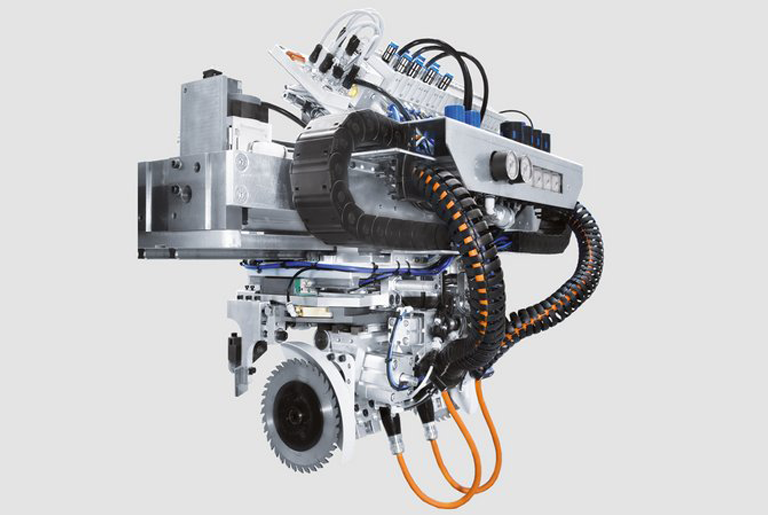

The single-sided Edgeteq S-500 edge bander offers precise gluing and perfect post-processing of edges, particularly suited for woodworking shops and medium-sized businesses where high performance is required. These edge banders have a selectable feed rate of 16-20, 25 (30) m/min. Automation and further functionality can be added, on an individual basis for these edge banding machines.

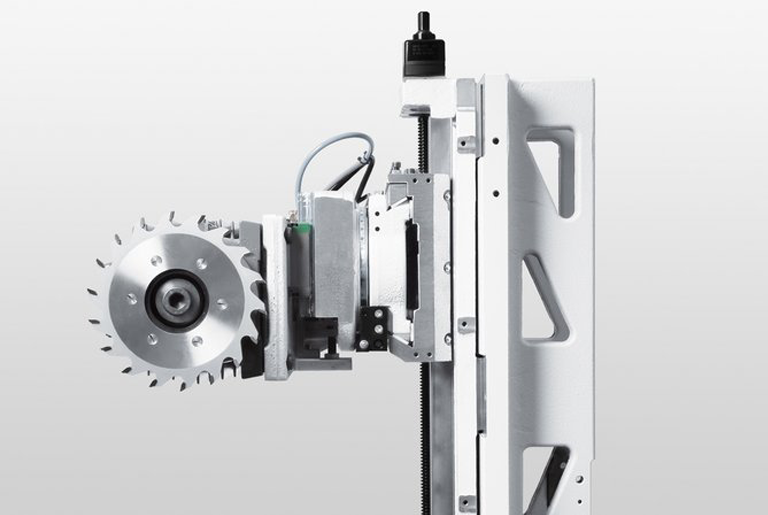

Processing rolls of material up to 3 mm, of strips up to 12 mm and alternative solid strips up to 20 mm is no problem for the highly flexible S-500 series. The finishing unit at the outfeed removes any glue residue and ensures the edges grip well.

For maximum efficiency, there is an automatic setup for different profiles. Also, for enhanced safety the Pneumatic dosing gate closes automatically, to avoid contamination and reduce the time and effort required for cleaning e.g. in case of a power failure.

Additional information

| Machine Category | New Machines |

|---|---|

| Machine Function | Woodworking |

| Machine Type | Edgebanders |

| Workpiece thickness [mm] | 8 – 60 / 12 – 60 |

| Edge thickness, coils [mm] | 0.3 – 3 |

| Brand | Homag |

Features

- Processing of rolls of material up to 3 mm, of strips up to 12 mm alternative of solid strips up to 20 mm

-

The finishing unit at the outfeed removes any glue residue and ensures the edges grip well

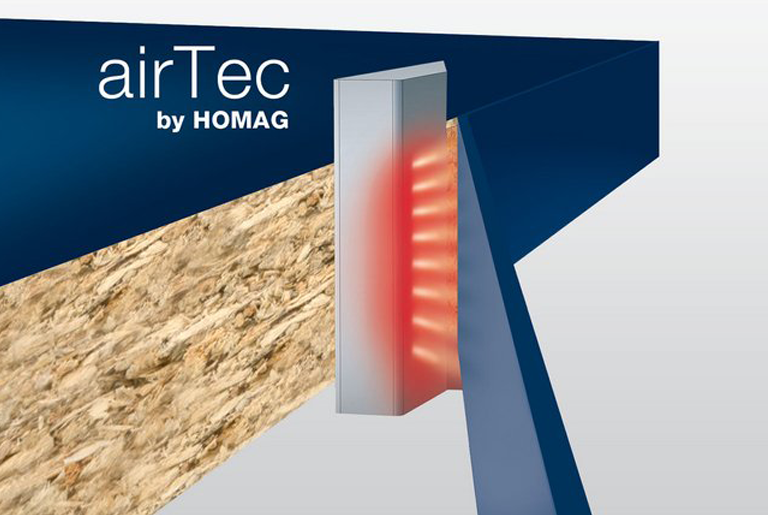

- Zero-joint technology with HOMAG airTec can be used

- Automatic setup for different profiles

Technical Data

| EDGETEQ S-500 | |||

|---|---|---|---|

| Machine dimensions | |||

| Overall length [mm] | dependent on the equipment | ||

| Feed speed adjustable [m/min] | 16 – 20 (25) | ||

| Working dimensions | |||

| Workpiece width [mm] * | |||

| with workpiece thickness 8 – 22 mm | 60 | ||

| Workpiece thickness [mm] | 8 – 60 / 12 – 60 | ||

| Edge thickness, coils [mm] | 0.3 – 3 | ||

| Edge thickness, strips / solid wood strips [mm] | 0.3 – 12 (20) | ||

* dependent on the workpiece thickness