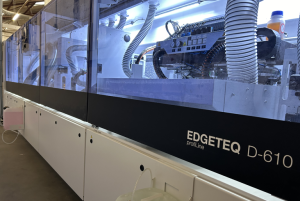

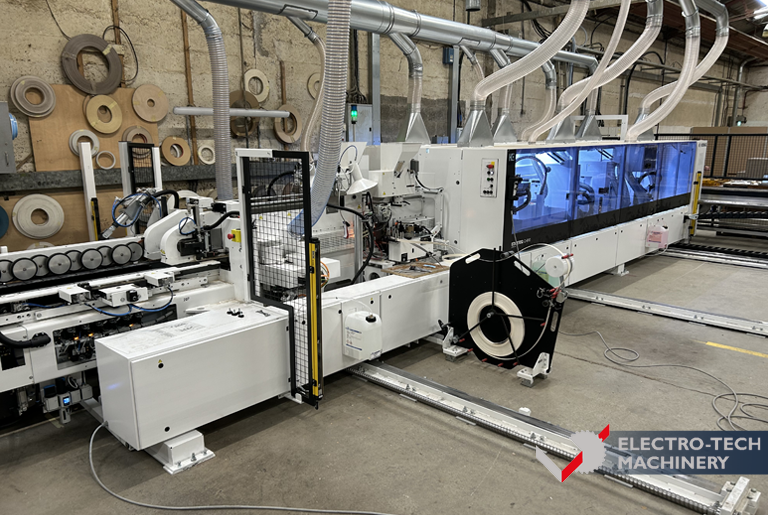

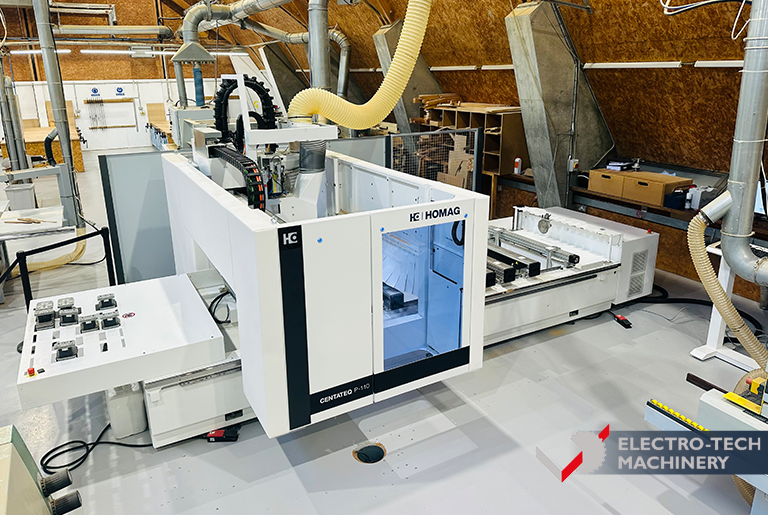

We are pleased to announce the successful installation of a state-of-the-art Homag Edgeteq D-610 Double-Sided Edgebander at a local company, marking a significant upgrade in their production capabilities.

Superior Workpiece Aesthetics

The Homag Edgeteq D-610 ensures a perfect workpiece aesthetic through its precise edge processing technology. The machine’s enclosed frame design facilitates vibration-free procedures, leading to optimal trimming patterns and high-quality finishes.

Unmatched Flexibility

This versatile edgebander accommodates various edge banding technologies, including hot melt glue, PUR, and zero-joint technology. This flexibility allows for various applications, catering to diverse production needs and ensuring top-tier results.

Enhanced Efficiency and Longevity

Optimized chip and offcut disposal systems are integrated into the Edgeteq D-610, enhancing machine availability and extending service life. This feature ensures our clients can maintain high productivity while reducing maintenance downtime.

Additional Features

The machine has an infeed table for easy feeding, a Nordson unit for efficient PUR gluing, and a grooving unit to achieve impeccable finishes. These components work together to deliver superior performance and reliability.

This installation represents our commitment to providing cutting-edge solutions that drive efficiency and quality in manufacturing processes. The Homag Edgeteq D-610 is now set to revolutionize edge processing at our client’s facility, paving the way for greater production excellence.

Please contact our team for more information about our machinery solutions.

Leave A Comment